A Proactive Approach is Best

If you are responsible for your condo or HOA’s physical condition, this is no time to relax. Planning now can pay big dividends in being able to hire a repair contractor before the spring/summer crunch arrives. With that in mind, the following list can provide a guide to issues for you to consider.

Building Maintenance Check list

- Inspect the roofs.

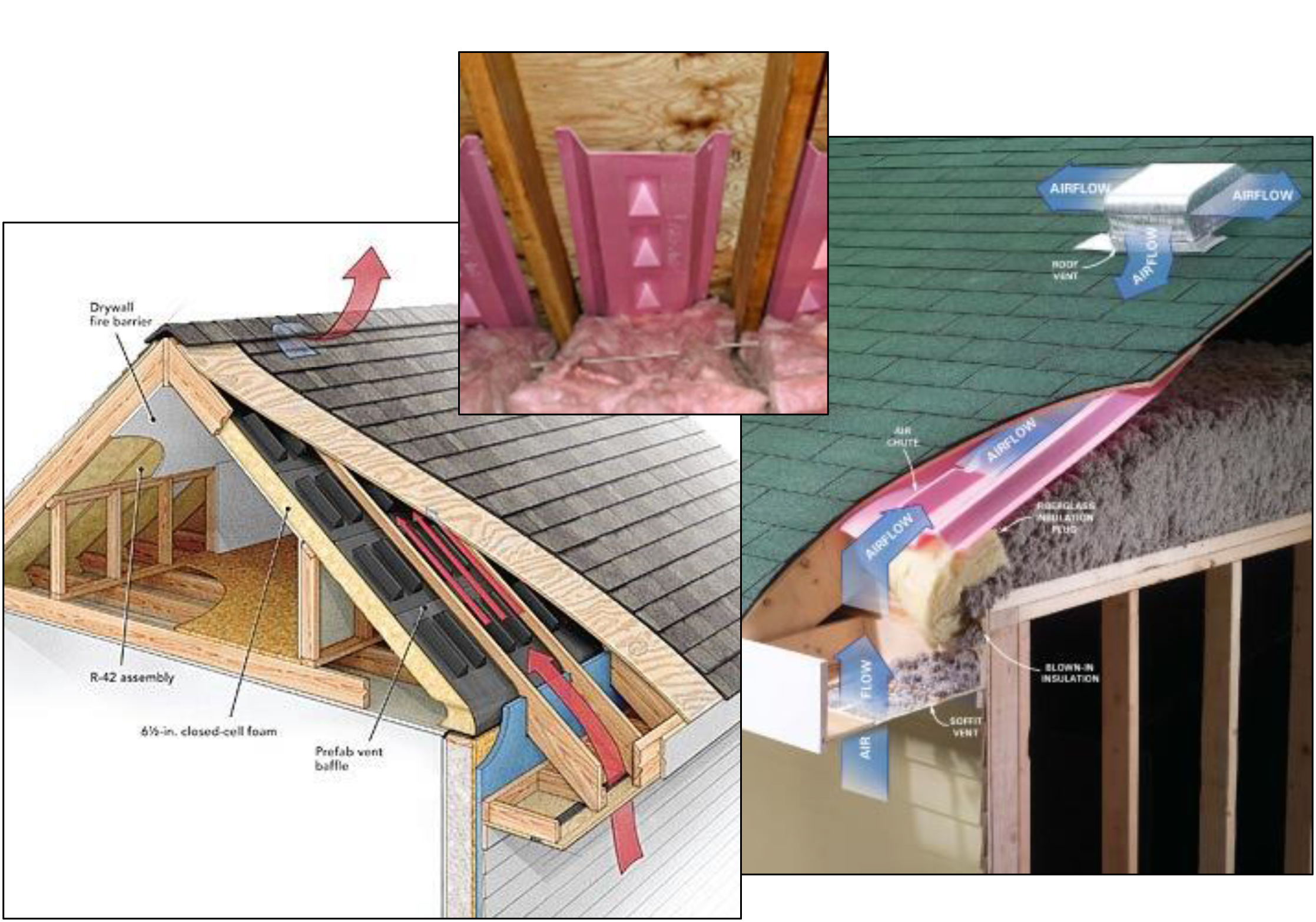

Too often, missing shingles and other storm related damage to roofs goes unnoticed during the winter. Now is the time for each roof surface to be scanned by eye, or better yet, by binoculars. Avoid going up on the roof unless it has a very low slope. Leave that to the pros. Other damage comes from removing ice dams and snow. Snow removal can be the cause of more damage than the actual snowfall itself. Most buildings are designed to handle snow, and it is very rare that even a large storm will dump enough snow to cause damage that will seriously harm your homes’ roofs. Let the snow melt naturally with the rain and warmer temperatures. - Gutter, downspout, and roof drain repairs.

Frozen gutters and downspouts can cause ice dams, but the most likely cause is building heat escaping due to poor insulation and/or inadequate venting of the air below the roof. Nonetheless, ensuring gutters run free to remove snow melt and spring rains is very important. Those condos with low-slope roofs and internal roof drains need to ensure those drains are clear of winter debris block water and causing surface ponding. - Ground surface drainage pathways.

Clearing out your drains on a regular basis will ensure they are free of debris for the summer thunderstorms. April and May are notorious for high quantities of rain no matter where you live. For communities located in snowy areas of New England, the additional water from the snow runoff can equal a great stress on the community’s drainage system. Avoid the potential of blocked drainage systems by habitually cleaning them every other month. Subsurface drainage culverts need periodic cleaning to ensure the winter sanding operation and other debris runoff has not prevented the proper storm drainage. - If you have a basement, check your sump pump regularly to ensure its operation throughout the rainy season.

The snow run off (or rain in warmer climates) can create an overload of moisture your sump pump may not be able to handle. Perform monthly inspections of the pump by opening the sump pit’s cover to clear any debris out of the bottom of the pit. - Replace snow stakes.

It’s a common mistake to replace the snow stakes only once a year, usually at the beginning of winter. The stakes can be the first thing to be damaged after a heavy snowfall, particularly if the snowplow knocks it over! - Landscaping plans. Landscaping can often take a hit during the cooler months. Recover quickly by bringing in your local specialist and discussing the various shrubs and flowers needing planting in spring.

- Send out paint bids for summer work. The major advantage to getting your bid requests out early is the extra time and accessibility your vendors are likely to have. Outside work requests often drop during cold weather and getting a head start will ensure your association is at the top of their list during the summer rush!

- Security enhancements. Now is the ideal time for associations to make the security enhancements they’ve been thinking about all winter. Security fencing and an alarm system are two timely projects for the post-winter months.

- Equipment rechecks. Even if pre-winter checks have been done, halfway through the winter is a good idea to do it again. Test emergency generators, keep batteries fully charged, check outside light fixtures are operational, ensure outside utility meters and hydrants are accessible, confirm clearance for both outside vents and exhausts, and change quarterly air filters.

Of course, this list focuses mainly on operating issues. When was the last time you took a hard look at your Reserve Fund Plan for capital repairs? Is your condo on schedule? Have things changed? Does the Reserve Study need a major update? Perhaps it is time a for a building condition survey to be conducted. This top to bottom review can be performed in-house or by a professional building inspector engaged to provide an informed, unbiased assessment of the physical condition of the various common building and site elements including siding, roof surface, structural framing, foundation, water infiltration, electrical, plumbing, HVAC systems, flooring, light fixtures, paving, and more. Providing a questionnaire to the unit owners during this process not only engages them in this important work but also may reveal common defects not readily known

Many maintenance projects have a double bonus—they will improve the appearance of your association while preventing costly repairs or replacements down the road. By undertaking some maintenance tasks now, you can lessen the costs many associations rack up in the rush to recover from winter.

Building Maintenance Check List – Article written by Jack Carr, P.E., R.S., LEED-AP, Criterium Engineers

Published in Condo Media

Download a PDF Version of this Condo Media article

Like people, no two condos are the same. Establishing methods of managing all types of condos by the same rules and standards is fruitless. A 40-year-old high-rise condo on the beach in York County needs a different maintenance plan than a community of new wood-framed duplexes in Franklin County. Following the collapse of the Champion Towers in Surfside, Florida, state legislators and condo industry leaders across the country have been scrutinizing past best practices of condo capital repairs with mixed results. As an example, earlier this year Florida signed into law the “Florida Condo Safety Act.”

Like people, no two condos are the same. Establishing methods of managing all types of condos by the same rules and standards is fruitless. A 40-year-old high-rise condo on the beach in York County needs a different maintenance plan than a community of new wood-framed duplexes in Franklin County. Following the collapse of the Champion Towers in Surfside, Florida, state legislators and condo industry leaders across the country have been scrutinizing past best practices of condo capital repairs with mixed results. As an example, earlier this year Florida signed into law the “Florida Condo Safety Act.” Ice forming inside of pipes often is not the cause for pipes breaking. Rather, water pipes

Ice forming inside of pipes often is not the cause for pipes breaking. Rather, water pipes  Make sure you actually need one, too

Make sure you actually need one, too

Cracks in foundations are by far the most common structural complaint raised in either reserve fund studies or transition studies. They can occur in the youngest or newest condo building. As condo documents usually assign the maintenance responsibility of their repair to the association, board members and property managers take them very seriously. Missouri condo buildings have many types of foundations including concrete block; brick; and mortared stone with the most common being poured concrete.

Cracks in foundations are by far the most common structural complaint raised in either reserve fund studies or transition studies. They can occur in the youngest or newest condo building. As condo documents usually assign the maintenance responsibility of their repair to the association, board members and property managers take them very seriously. Missouri condo buildings have many types of foundations including concrete block; brick; and mortared stone with the most common being poured concrete.